Deep Water Riser &

Flowline Pipe Machining Services

ID & OD Counterboring | Beveling | Line Boring | Coating Modifications

Deep-Water Pipe Machining Services

Bevel Tech Group, Inc. is a leader in machining steel catenary riser (SCR) and flowline deep-water pipe projects. For two decades, our specialized services have been trusted by major oil companies, lay-contractors, engineering firms, and pipe manufacturers worldwide for Deep-Water Project support.

We have partnered with industry leaders to deliver expert pipe cutting, OD and ID counterboring, coating removal, modifications, and other specialized services tailored to the needs of the Deep-Water oil and gas industry. Our fully equipped, highly trained staff of specialists is dedicated to meeting the rigorous standards of your SCR Deep-Water projects, ensuring quality and reliability every step of the way.

Our state-of-the-art CNC machines, loading racks, and supporting equipment are continually engineered and updated to adapt to our clients’ evolving demands and specifications. Designed for portability, this equipment can be shipped globally, allowing us to provide counterboring and other Deep-Water services wherever they are needed.

OD Pipe Counterboring

Outer diameter pipe end machining for alignment and welding in various applications. Our innovative solutions are designed to address the unique needs of our clients and drive success.

J-Collar Fittings

Machined to pipeline requirements for ease of alignment, welding, and testing during pipeline installation.

Line Boring Riser Cassette

Utilizing the precision of laser measurement with the proprietary Faro laser, Bevel Tech Group can deliver tolerance to less than 0.001 of an inch.

ID Pipe Counterboring

Utilizing Bevel Tech Group, Inc.’s proprietary mobile CNC, these systems can deliver tolerances well within industry and manufacturer specifications. Mobile units can be shipped to customer sites both domestically and internationally for field operation.

Coating Removal

Custom coating removal for client-specific needs, including qualification testing and R&D Projects. Experienced in removing microsphere syntactics, singular resins, and hybrid systems used throughout the subsea insulation market.

Pipe Beveling on Deep Water Pipes & Structures

Hands-free pipe beveling for use in the horizontal and vertical positions for field machining solutions. All equipment and tooling are 100% owned by Bevel Tech Group for immediate deployment to customer sites.

Induction Bends Counterboring

Induction bend tangents counterbored for higher fidelity weld and test results. Available for onsite or in-house machining to meet each project’s needs.

Deep-Water Fatigue Pups

Ensuring accuracy in each pup as required to meet industry and installation standards.

Pipe Coating Modifications

Client coating modifications to meet installation and testing requirements with lay contractors and test houses.

ADDITIONAL PIPE MACHINING SERVICES

OD and ID Counterboring

Pipe Cutting and End Beveling

Pipe Coating Removal and/or Modification

Buckle Arrestor Machining

Cutting and Machining of Fatigue Joint

J-Collar Machining

Machining of Induction Bends

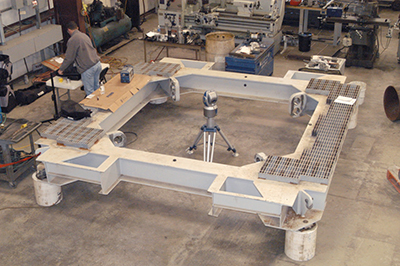

PLETS / PLEMS / A&R and Tailing Heads

Mechanical Equipment Repairs & Preservation

Pipe Dimensioning (Conventional or Laser)

Offshore Technician Support