Marine Services

KEEPING YOUR FLEET MOVING

Confidence in solutions

Installation of Machinery

Bevel Tech Group, Inc. understands the need for proper installation and chocking services of facilities and marine machinery. We use industry-leading products to ensure the project is completed safely, correctly, and on time.

Laser Alignment & Machining

Bevel Tech Group, Inc. utilizes laser alignment technology to ensure the fit of the line bore of propulsion shaft bearing seal areas in stern and strut tubes, and in Z-Drive steering column seat areas. Bevel Tech Group can also supply sleeve material to meet our customers’ specific needs.

These services allow our customers confidence in ship operations and execution of these services is supported by Bevel Tech Group’s mobile fleet of experienced field machinists and senior quality technicians traveling across the US to customer sites, dry docks, and ports.

All safety requirements for port entry and OSHA standards are updated yearly for all staff, and the equipment is 100% owned and in stock for immediate deployment to the job site.

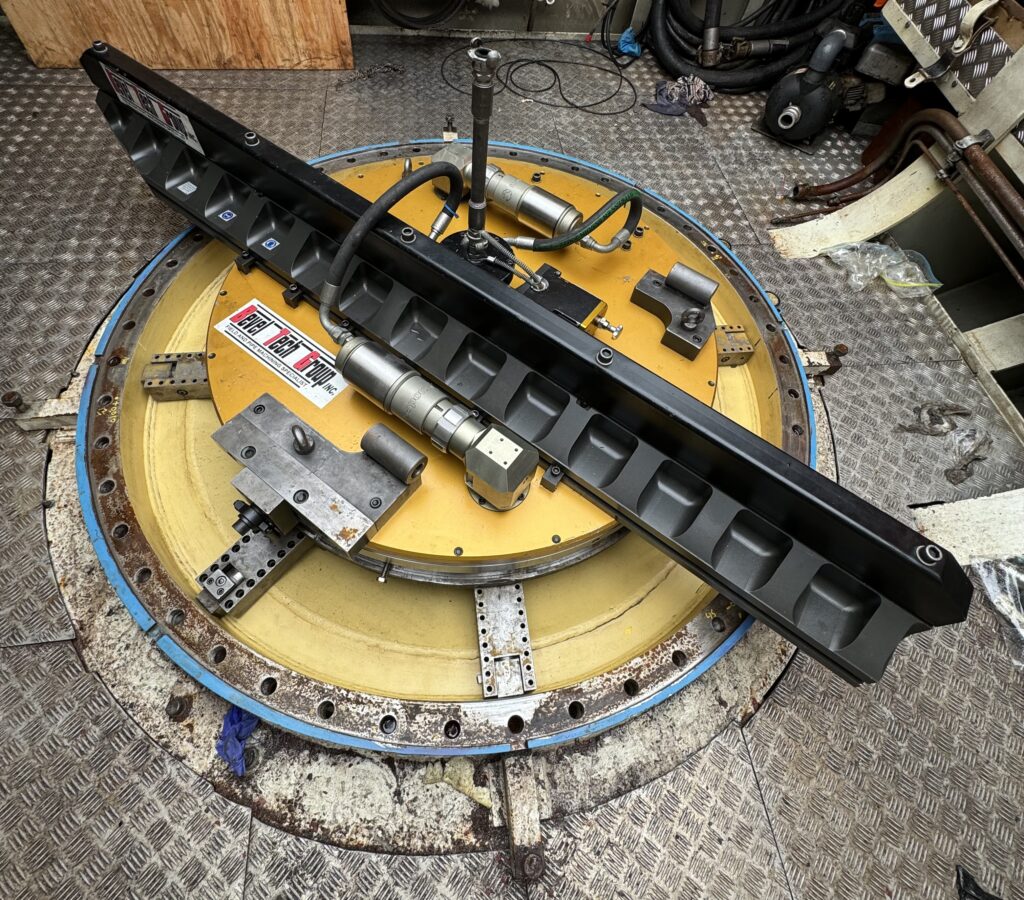

Z-Drive Alignment & Machining

Bevel Tech Group, Inc. is a trusted source for ensuring the fit of your Z-Drive, regardless of brand, has a flange properly aligned for a seamless fit.

For new installs or scheduled maintenance, Bevel Tech Group is ready to partner with your team to ensure the alignment is done right the first time to keep your fleet doing what it does best, moving cargo and delivering for your customers.

Chocking of Equipment & Structures

Bevel Tech Group, Inc. is a trusted partner for the preparing, supplying, and pouring of chocking grout compounds. These services are provided using industry-leading resins and grouts to ensure the project is completed on time and within budget.

Not all installations are the same and choosing a proper partner like Bevel Tech Group can make the difference in keeping within tight schedules and prevent costly rework delays.

The Benefits of Resins & Grouts:

Maintain Alignment

No shrinkage, high stability, and modulus of compression in the long run. This makes them appropriate for applying in critical alignments.

Absorb Vibrations

They reduce vibration and noise levels by maintaining bolt-tightening stress and filtering part of the vibrations.

Quick Mounting

Resin application can be done in a few hours and does not require machining or adjustment of the seat or metal chocks.

Bigger Resistance

Excellent resistance to compression and degradation due to contact with oils, fuels, seawater, and chemicals.

Less Maintenance

They avoid bolt breakage because stress is maintained on them. They do not need maintenance because the chocks do not wear out.

More Reliability

The installation process and grout resins are certified by all classification societies.