100% OWNED IN-STOCK EQUIPMENT

Industry Leader Delivering Unmatched Quality

Bevel Tech Group’s reputation as a premier field and shop machining contractor is built on our commitment to Safety, Precision, and Reliability. With our highly trained technicians and cutting-edge hands-free machinery, we deliver top-tier results, consistently meeting the strictest tolerances and production standards. We own a wide range of flange-facing machines in various sizes, allowing us to accommodate any job, no matter the scale.

Whether you’re planning a scheduled outage or facing an emergency, Bevel Tech Group’s portable machining equipment and expert technicians are ready to meet your needs. Available 24/7, we ensure that your operations run smoothly, no matter where you are in the United States or around the world.

Upside Down Vertical Flange Facing

Machining the face of the housing for a crane pedestal interface to ensure proper alignment and fitting – Upside down without issue!

Custom Field Boring Applications

Custom tooling configured to machine a seal face for a tanker truck in the field. All are designed for a safe hands-free configuration and completion.

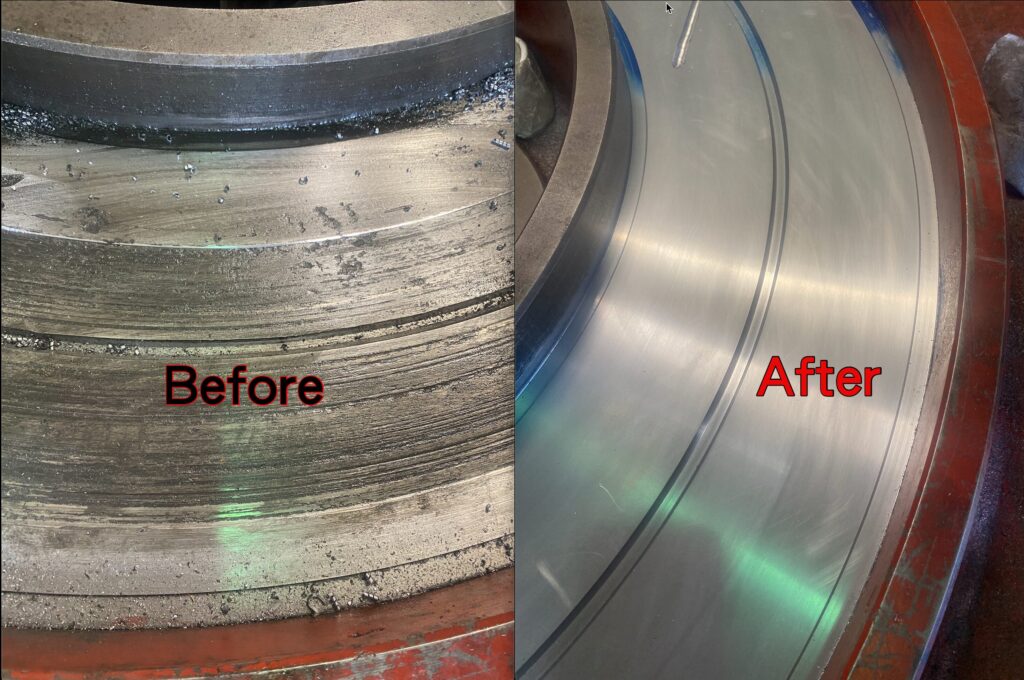

Machining VTL Bearing Area

Customer onsite machining of natural wear and tear to restore VTL to optimal performance – completed handsfree

Pipe Cut & Beveling 3.5 Inch Heavy Wall Wellhead

Specializing in the precision machining of heavy wall pipes for high-pressure systems, Bevel Tech Group, Inc. supplies hands-free onsite field solutions.

Field CNC Counter Boring of A&R Head

Providing the customization of a large machine shop onsite for varied client settings, such as this Abandonment and Recovery (A&R) Head. These heads are used in offshore oil and gas engineering to lower pipelines to the seabed and lift them back up.

Flange Facing 18-Foot Crane Pedestal

Ensuring the accuracy of fit is critical on all parts, large and small. Bevel Tech Group has solutions ready to address these larger projects with in-house custom equipment.

Flange Facing 144 Inch Cradle Bearing Base

Our team is dedicated to providing superior customer service and unmatched quality – in the field, your shop, or ours!

Line Boring Crane Boom

Delivering onsite support within client specifications and operating needs to maintain client’s needs is our passion. Bevel Tech Group, Inc. is consistently providing safe and innovative solutions as the partner of choice for field machining needs.

Line Boring Grout Bung Assembly for Locater Pins

Efficiency and speed on specialized client requests.

Additional Selection of Services

Flange Resurfacing

Broken Stud Removal

Drilling &Tapping

Line Boring

Millwright Work

Portable Milling including Pump Bases, etc.

Boiler & Furnace Tube Cutting, Removing, or Beveling

Heat Exchanger – Bundles & Heads

Shaft & Seal Repairs

Pipe Cutting & Beveling

PIP Track Beveling

Pipe Coating Removal

Buckle Arrestor Machining

Fatigue Joint Machining

OD & ID Machining

J Collar Machining